Porsche 914 Turbocharged Chevy 350 V8 PorChev

- Make: Porsche

- Model: 914

- Type: Convertible

- Trim: Turbo

- Year: 1973

- Mileage: 4,100

- VIN: 4732900348

- Color: Black

- Engine size: 350 Chev

- Number of cylinders: 8

- Power options: Air Conditioning

- Fuel: Gasoline

- Transmission: Manual

- Drive type: RWD

- Interior color: Black & Gray

- Vehicle Title: Clear

- Interested?

1973 Porsche 914 Turbo Description

Porsche 914 Turbocharged Chevy 350 V8 PorChev

Fresh out of barn storage. The 914 project car I've had for nearly 30 years. Who would be interested in such a dirty un-kept piece of dung, covered in dust, surely a throw away, hardly fit for your time wasted in contemplation. How could anyone, after seeing these first few pictures ever consider pursuing a purchase of it.

After a quick clean up, hardly any and no detailing. At least you don't see the rats, acorns, saw dust, hornet nets, dead octopuses and cow dung!

It all started from a long history of owning and modifying many vehicles such as a 1967 Austin Mini Cooper 1275S (supercharged), 1962 Alfa Romero Giulietta Zagato Sprint, Austin Healy 3000, building a '41 Willys A Gas class drag car (idolizing Stone Woods & Cook of Lyons Drag Strip), driven daily to high school, a 1956 Porsche Speedster, then restoring a Briggs Cunningham C2R (one of 4) LeMans race car. Motorcycles with turbochargers too, they were designed for performance, they were interspersed with many other cars, along with a Crown Engineering prototype '65 Corvair Corsa Turbocharged car used for it's performance parts design and testing. That led to building 3 mid-engined Corvairs, constantly evolving them. Along with them, owning a standard 914, and then a 914/6. The evolution had taken another step. They were all special in their own way. The Mini, Porsche Speedster, 911 and 914/6 were great handling but needed something more. This brought about what you see here, a 914 conversion project began many years ago. It had to be fun, comfortable, easily drivable, functional, exceptionally agile and fast. It could not be problematic, unreliable, costly and time consuming to use and own. The entire idea was to build a super performance car with exceptional handling and straight line performance but able to be easily driven on a daily basis. At the same time bringing this about with low maintenance and easy servicing which can spoil the whole deal if not accomplished. The dream of owning a high performance car can become a nightmare in costs, problems and down time.

Starting with a naked stripped shell, all design changes, fabrication and welding fitment was done, reinforcement plates and gussets added and clean metal was then prepped for painting. New hardware, wiring and anything else needed was replaced. Building cars was my passion. Owning and modifying some 50 vehicles had given me the experience to know what I wanted. Then, having previously built three 1964-5 mid-engined Corvairs, then building the first 914 V8 followed by this car as the final step in the design evolution.

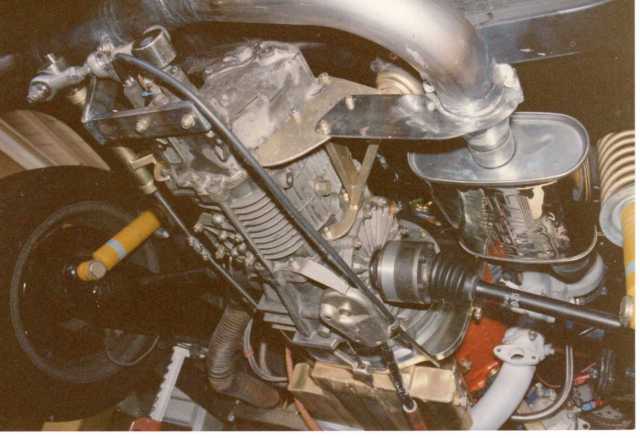

Here are some pictures which documented the building process. The original engine was a naturally aspirated de-stroked 327 to 288. Gradual raising redline to 8200 rpm. It eventually was replaced with a hybrid turbocharged Chevy 350. Starting with a fully machined squared block, ARP fasteners, TRW 8.6 : 1 compression pistons in .030 over bore. Rods are factory performance issue with beam work, then shot-peened. Chevy crank was shot-peened and nitride heat treated. Bow Tie factory aluminum heads assembled with stainless valves and high ratio roller rockers after CC'ed porting and chamber matching. Solid copper head gaskets were used with a compression ring imbedded into the block (or head, can't recall which I chose) surface around each cylinder bore. This solved all the problems under very high boost pressures. Billet aluminum accessory brackets hold the Hemi water pump with custom housing, alternator and air conditioning. The solid mounted engine support also serves as a chassis stiffener. Standard Chevy motor mounts are used to eliminate extra noise and vibrations (not solid mounted, which is way easier to do). Engine and Trans package mounting is all custom made, no kits. The adapter and water pump housing was from PorChev, if I recall. He was the first in the early 1970's to do a Porsche conversion. Tildon geared starter works flawlessly on the small diameter (extra torque needed) flywheel. A special race baffled w/trap doors 10 quart oil pan was custom made to fit around all the hardware. The center balance point was located and a custom jack point was made as part of the oil pan which you will see pictured. That really saves bunches of time in the engine package removal or installation from underneath.

The Turbo is a hybrid cross breed of a Rajay and Air Research. Turbonetics originally designed it to increase boost while shortening lag time. The Porsche Carrera 915/930 trans was fitted with highest Porsche gear ratios available with the ring gear flipped during the build. Everything about the car was hand built as a one off.

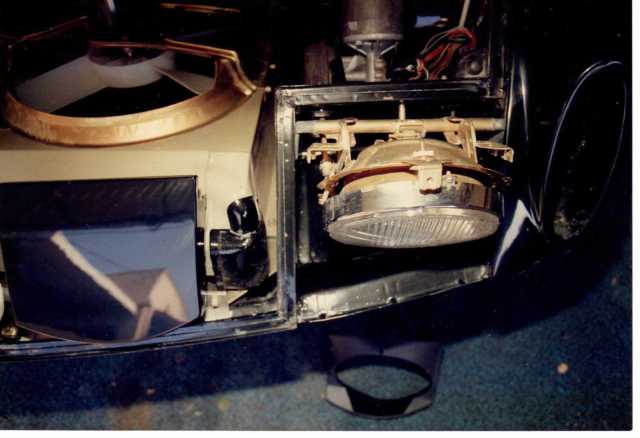

Extensive uni-body structure and suspension arm gusseting was fitted. Stiffening everywhere possible without compromising the utility as a daily driver (no roll bars or odd solutions). Inside the rear trunk shows a welded in stiffening cross bar still allowing the Targa Top to be stored as original. Custom built cooling system fabrication with Air Conditioning and 3 supporting thermostatically controlled fans were incorporated in the custom ducting and mounting. Over several years the cooling system evolved to track tested success under maximum conditions providing efficient cooling levels while A/C was running. Aluminum shroud and detailed venting makes the cooling system could appear to some as original equipment.

A set of Recaro seats were fitted as low as possible on fabricated OE tracks. An aluminum black anodized under-dash center console was later constructed after a wood one (showing) was perfected. Stout shift mechanism design was designed using a 911 tower inside. 911/930 front suspension and steering was installed. Bilstein shocks on all corners. Large 911 brakes used on the front and rear with an adjustable rear brake proportioning valve. A hydraulic fluid lock is use for as parking break on the rear discs. Both doors underwent modification for speaker/tweeter mounting as part of the quality sound system install. Also fitted with 911 Side Mirrors with factory 911 adjustment switch (pictured). Instrument cluster was replaced with 911 gauges and an AutoMeter 10 grand tach. The usual gas combo gauge is mounted in the under-dash center anodized aluminum console (ready to install). Boost pressure regulation is done from the dash through a waste gate. An Amp is mounted inside the console and the radio was mounted in dash using a quick slide out tray. There a few anti-theft implementations which I must remember to tell the new owner. An efficient heater was fabricated to replace the hot air from the original air cooled engine. Pictures show it well. All plumbing is copper, stainless and Aeroquip stainless braided aircraft lines. Stainless and aluminum are used exclusively in the adaption. Most of the fasteners are either aircraft 12pt or Allen head bolts.

Custom exhaust utilizing Turbonetics cast iron manifolds for heat retention, a custom cross over and exhaust system was hand welded with cut bends in standard racecar construction (no squished bends, all hand built). The exhaust is supported with solid direct mounting to the engine package, eliminating any flex, all moving together with the engine as one piece. The sound, when idling at a stop is similar to a pulsed jet, nothing like you've ever heard.

All brackets, fasteners, hinges, everything that could be unbolted was Cadmium plated with a chromate conversion coating called Cad 2 in typical aviation style. Aircraft securing clamps were used everywhere. All assembly was done after painting. Painting everything as a shell with all the reinforcements welded in, before any assembly, consisted of etching base primer, epoxy build primer and catalyzed black paint. After many hours of block, guide coat, blocking again, over and over in preparation, the only way to get this straight and true result. The contrast of all the gold plating cad-II plating against the glistening black was worth all those extra hours.

The car was intended to be a "sleeper". People would always look around for what's making those unusual throaty exhaust sounds. The front and rear fenders were flared out without really making it obvious. You have to look to see it. If you didn't know the 914 well, you'd probably not see them. The Minilite Magnesium wheels are constantly darkening under any painted clear coating. Other than the original the few remembering 1960-70's Halibrand magnesium wheels, I still think they are one of the prettiest wheels ever made.

The carburetion system was in constant change. Currently fed by a Holly pump pushing fuel from under the front mounted tank. Pumping fuel to the aircraft aluminum filter which features cleaning the fine brass screen inside by twisting the "T" handle on top. Added to that, an adjustable pressure regulator and aircraft shut-off valve which can be seen with this filter in the engine bay. When using carburetion, pulling the air through instead of pressurizing is the only way to efficient turbo charging, especially when exceeding 10 psi (.8 BAR). This system is capable of nearly 30 psi (2+ Bars) boost. The next evolution was to upgrade to the Electromotive EFI / Ignition combined system with the a pressurizing (blow through) commonly used today. Electromotive offered the only system available with programmable +-60 degrees advance/retard timing and adjustable fuel to synched to boost pressure as programmed criteria needed for this car. I have the system components for this change which will be available separately (first to the new owner).

The following pictures were taken over many years. Some showing the day it returned from the paint shop and onward in the process of final assembly. In 1992 the car and all its spare parts were stored due to a cross state move, beginning of a family and the building of a house. It is now, being brought back into the light and made available to you. Some engine components may be dated and the new owner might want to change. The basic structure is not one of them. There is so much to convey, let alone remember that I surely cannot list it all here without monotony.

There are boxes of spare parts that will go with this car, including another Targa Top, completed anodized aluminum center console with gauges, extra tubocharger compressor impeller and more. Way too much more to go through and itemize, so you get to do that.

Electromotive EFI with ignition, contact trigger crank wheel, sensors, ECU, Pumps, Manifold (Torker), complete valve body and most everything else needed for a complete retrofit will be made separately available to the car's new purchaser.

This item can be removed from the store at any time. It is available locally and through other vendors.

Available on Craigslist

Check our eBay store for related items.

Our eBay Auctions Sales Policy

TURBOCHARGED 4.8L V8, AWD, NAVIGATION, FULL LEATHER, VERY CLEAN PORSCHE

TURBOCHARGED 4.8L V8, AWD, NAVIGATION, FULL LEATHER, VERY CLEAN PORSCHE

Mileage: 76,423

2017 Porsche 718 Boxster 1674 Miles Black 2D Convertible 2.0L Turbocharged 6-Sp

2017 Porsche 718 Boxster 1674 Miles Black 2D Convertible 2.0L Turbocharged 6-Sp

Mileage: 1,674

2011 Porsche 911 Turbo S 10395 Miles 2D Cabriolet 3.8L 6-Cylinder Turbocharged

2011 Porsche 911 Turbo S 10395 Miles 2D Cabriolet 3.8L 6-Cylinder Turbocharged

Mileage: 10,395

2017 Porsche 718 Cayman S 322 Miles 2D Coupe 2.0L H4 Turbocharged DOHC 16V 350h

2017 Porsche 718 Cayman S 322 Miles 2D Coupe 2.0L H4 Turbocharged DOHC 16V 350h

Mileage: 322

2011 Porsche Panamera Turbo 4.8L V8 Turbocharged Engine 30,879 Miles Hatchback A

2011 Porsche Panamera Turbo 4.8L V8 Turbocharged Engine 30,879 Miles Hatchback A

Mileage: 30,879

2011 Porsche Panamera Turbo PDK 30995 Miles, Black Sedan 4.8L V8 Turbocharged E

2011 Porsche Panamera Turbo PDK 30995 Miles, Black Sedan 4.8L V8 Turbocharged E

Mileage: 30,995

2008 Porsche 911 Turbo 32711 Miles Black 2D Coupe 3.6L 6-Cylinder Turbocharged

2008 Porsche 911 Turbo 32711 Miles Black 2D Coupe 3.6L 6-Cylinder Turbocharged

Mileage: 32,711

2011 Porsche Panamera Turbo 4.8L V8 Turbocharged Engine 30879 Miles Hatchback Au

2011 Porsche Panamera Turbo 4.8L V8 Turbocharged Engine 30879 Miles Hatchback Au

Mileage: 30,879

2011 Porsche Panamera Turbo 4.8L V8 Turbocharged Engine 30879 Miles Sedan Automa

2011 Porsche Panamera Turbo 4.8L V8 Turbocharged Engine 30879 Miles Sedan Automa

Mileage: 30,879

2011 Porsche Panamera Turbo 4.8L V8 Turbocharged Engine 30880 Miles Sedan Automa

2011 Porsche Panamera Turbo 4.8L V8 Turbocharged Engine 30880 Miles Sedan Automa

Mileage: 30,880